Tools and accessories

The complete range of accessories (tools, compressor) for Scrap’Air pneumatic tools available here.

High Resistance, Versatility and Quality: Why Scrap'air Tools are Essential for Professionals

Scrap'air tools are renowned for their high strength and versatility, making them indispensable allies for demolition and renovation professionals. Here are the main advantages of Scrap'air tools, designed to meet the most demanding requirements on building sites:

1. High strength and durability

Scrap'air tools are made from high-quality hardened steel, giving them exceptional strength. This robust design ensures long life, even in the most demanding working conditions. Surface shot-blasting gives the tools extra protection against oxidation, preserving their performance over time.

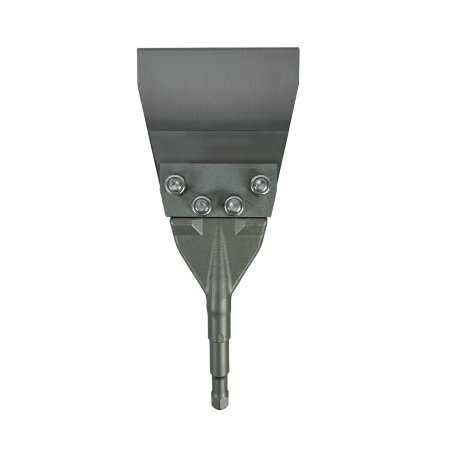

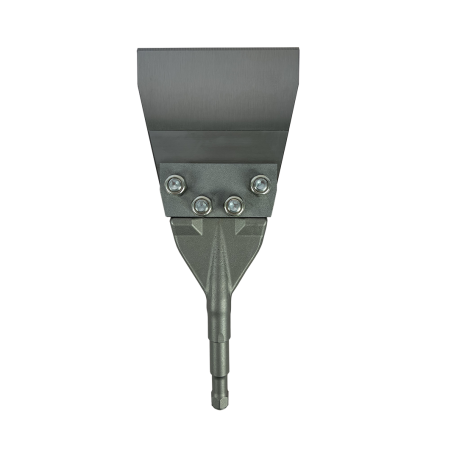

2. Intuitive, safe installation

The installation of Scrap'air tools is designed to be intuitive and quick, guaranteeing simple and safe tool changes. This minimises interruptions on site, increasing productivity. The hexagonal shank reduces tool wear, extending tool life and ensuring safe use.

3. Versatility of use

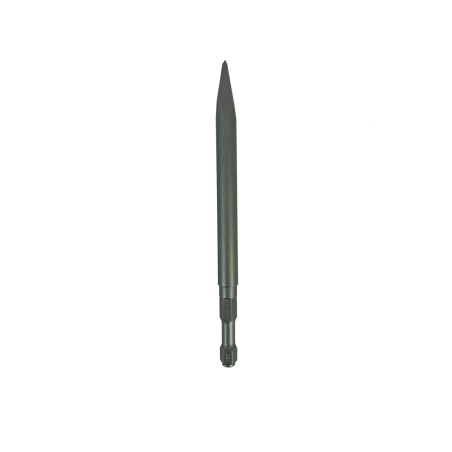

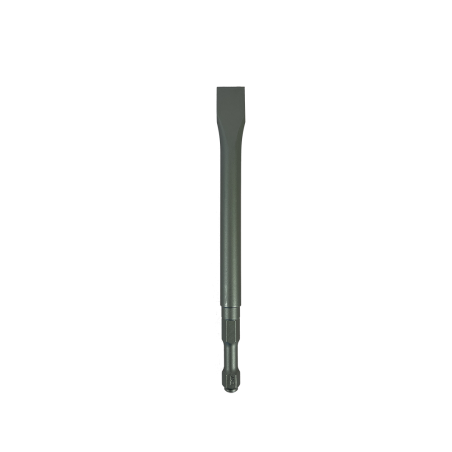

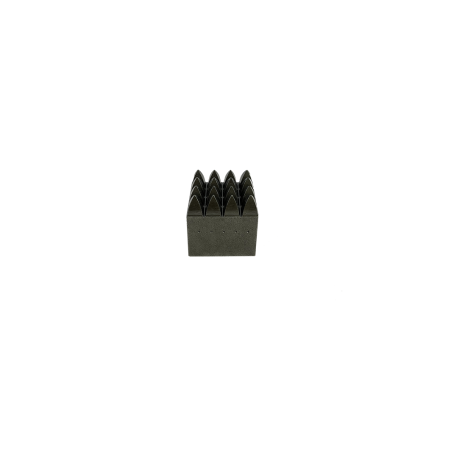

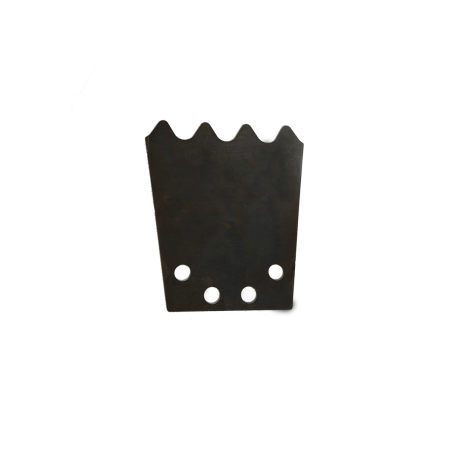

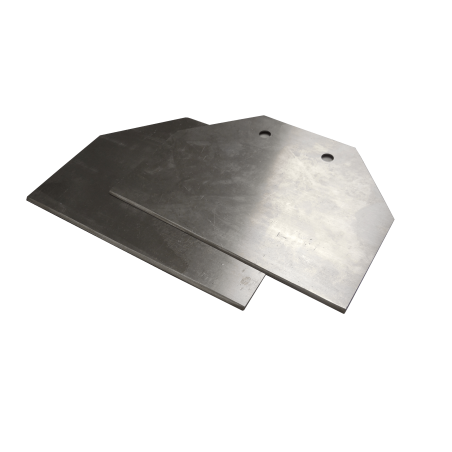

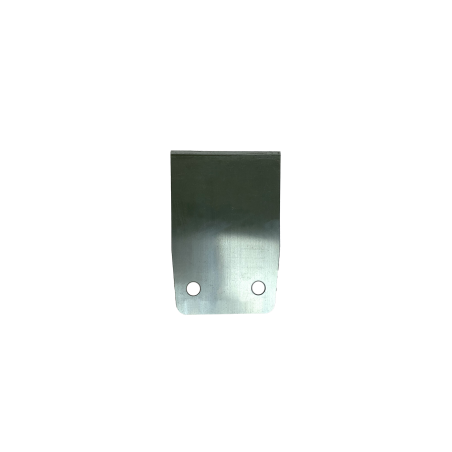

Scrap'air tools offer a multitude of applications in a single device, making them extremely versatile. Depending on requirements, the user can adjust the angle of attack and choose the appropriate tool:

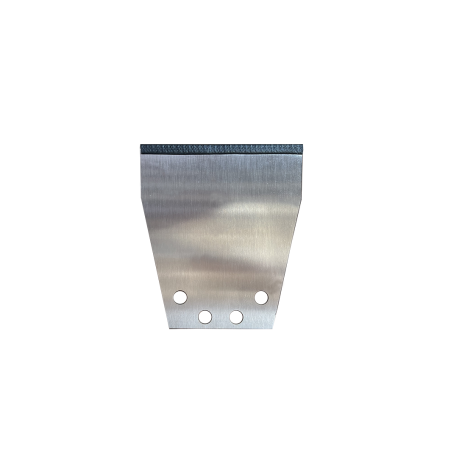

Low angle of attack: Ideal for using wide, curved knives, perfect for protecting the substrate while stripping friable materials.

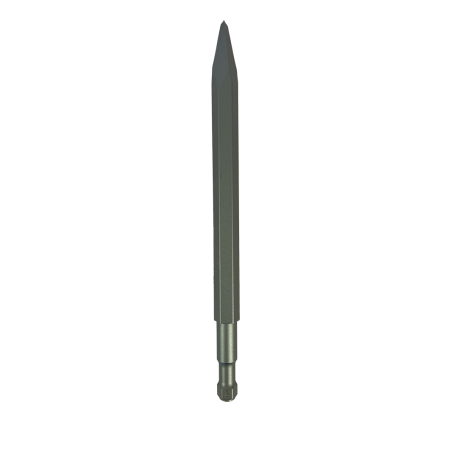

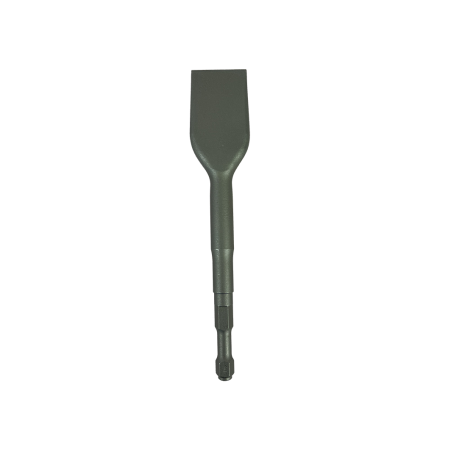

High angle of attack: Suitable for fine, straight chisels, enabling them to penetrate the substrate and strip hard, resistant materials.

4. Adaptability for all needs

Each Scrap'air tool is designed to adapt to different site requirements. Whether it's a delicate job requiring a low angle of attack, or an intense demolition task requiring high impact force, Scrap'air tools offer the right solution.

5. Quality recognised by professionals

Scrap'air tools, made in Germany, are developed with consistent quality, year after year, and are widely recognised by professionals in the sector. Their reliability and performance in the field make them the tools of choice for demanding users.

Invest in Quality

By choosing Scrap'air tools, you're investing in heavy-duty tools designed to last and deliver unrivalled performance. Their intuitive use, versatility and adaptability make them indispensable tools for all professionals looking to maximise their efficiency on the job.

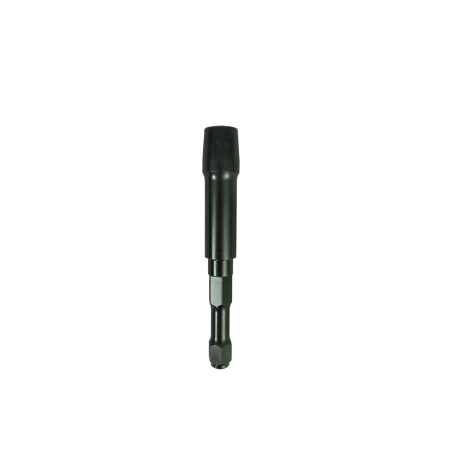

14 mm vs 18 mm Shanks: Differences in Robustness, Compatibility and Use

14 mm and 18 mm diameter shanks refer to the size of the tool section that is inserted into the machine (such as a jackhammer, pneumatic chisel or other demolition tool). This difference in diameter has a number of implications in terms of performance, compatibility and use. Here are the main differences between these two types of shank:

Robustness and strength

18 mm shank: Wider, this shank is generally more robust and better suited to heavy, intensive demolition work. It can withstand higher impact forces without the risk of deformation or rapid wear. It is therefore recommended for applications where high power is required. Tools for Scrap'air 55 only

14 mm shank: Thinner, this shank is generally used for lighter work or smaller machines. It is less resistant than the 18 mm shank and is better suited to tasks requiring less force or greater precision. Tools for Scrap'air 24 /36 /38 only